The issues dogging connected lighting systems still persist

By Ruth Taylor

The recent U.S. Department of Energy (DOE) Solid-State Lighting Virtual Workshop (January 31-February 3) highlighted the two faces of connected lighting systems: far-reaching potential and stubborn problems.

The potential has been well documented: progress toward a clean-energy future with integrated lighting and HVAC systems, enhanced well-being from adaptive lighting systems, and increased asset performance from rich usage data, among other benefits. We well understand that diverse problems continue to slow adoption of connected lighting systems and dog many of those installed to date. But the need for action is important and is now coming into focus.

We’ve collected data on the challenges facing connected lighting systems through our work in the Living Labs of the Next Generation Lighting Systems program. Corroboration comes from DOE’s Commercial Buildings Integration (CBI) program, which has been conducting field validations of integrated lighting systems. In addition, the DOE Solid-State Lighting program sponsored the CLS Stakeholder Research Study by Guidehouse, as well as PNNL’s ongoing research on tunable lighting systems in realistic settings and a recent series of interviews with lighting professionals along the entire market chain. In short, research reveals problems all along the way, from manufacturer product development through operation by end users and ongoing maintenance.

If you think that current practice will resolve these difficulties down the road, that it takes time for the problems in systems to work themselves out, here’s a wake-up call: These issues were discussed as far back as 2015, when DOE convened its first Connected Lighting System Workshop. Back then discussion centered around technologies that users couldn’t figure out; configuration complexity; and expensive, time-consuming, even painful commissioning. These same issues persist today. Moreover, systems don’t work out the problems, people do.

The overarching problem remains complexity due to the uniqueness of each connected system compounded by entangled industry practices. The use of a building and needs of its owners make every system and installation a one-off. Buildings are all different, as are the products used and their interactions. As a result, those involved in the installation of a connected lighting system believe their problem must be unlike anyone else’s. But it isn’t; evidence is clear that these problems are recurring. Work-arounds can get the systems to function, more or less. But such quick fixes don’t address the core problems and don’t prevent them happening again in other installations.

Given the stakes involved as well as the nature and complexity of the challenges inhibiting connected lighting systems from their full potential, what do we do next? What steps do we take to achieve alignment and a forward push?

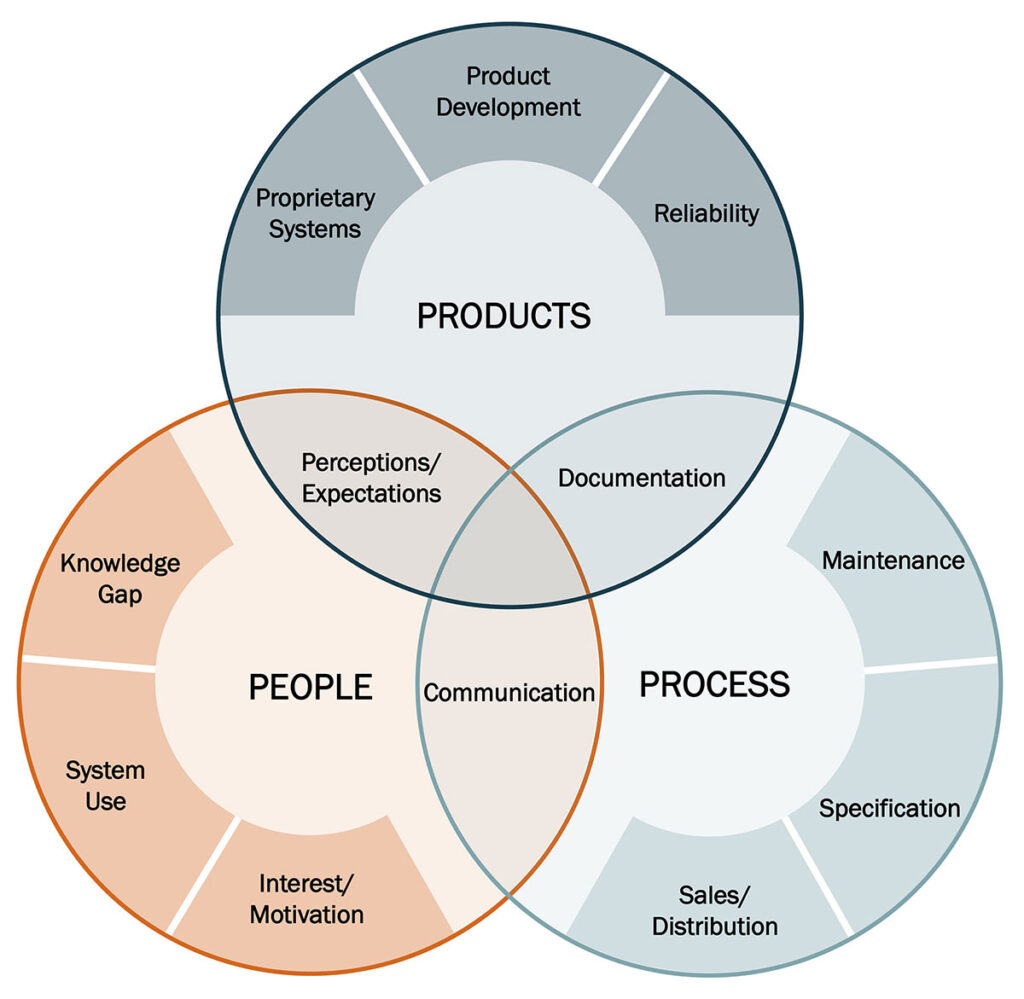

Considering problems and possible solutions in three clusters may help: products, processes and people. Several presentations at the Solid State Lighting Virtual Workshop suggest how the clusters can identify key targets for improvement.

In his presentation, Mike Skurla of Radix IoT stressed the idea of consistency in connected lighting systems and identified the many ways proprietary design weakens consistency: proprietary hardware, proprietary setup, proprietary communication, proprietary service and so on.

In her workshop presentation, Carol Jones of Axis Lighting referred to interoperability as the “holy grail” for the lighting industry. She described current “interoperable” IoT systems as single-manufacturer systems with proprietary aspects, such as the luminaire. She said we in the lighting industry need to be moving toward open protocols at the luminaire level through DALI, Zhaga and NEMA standards. In this respect, North America lags Europe in the acceptance of such standards.

U.S. manufacturers have yet to move toward available open protocols because of the cost involved and the impact on the time to develop and release products, and—critically—limited demand to date. So far, we seem to favor speed to market with distinctive features and a focus on the next big thing. Another issue is testing, which becomes problematic given the complexity of the systems. We need to recognize the rewards for consistency, reliability and utility that the market can deliver and move toward this paradigm.

The workshop session entitled “Taming Advanced Lighting System Complexity: A Call to Action” looked at challenges with configuration, commissioning and maintaining control settings over time—barriers that keep us from future integration with other building systems. This panel focused on the need for development of a clear and concise Sequence of Operations or SoO as an important solution to many of the communication challenges plaguing connected system installation and configuration.

LD+A columnist Charles Knuffke of Wattstopper called the SoO a “must-have document” that identifies in detail the level of complexity of the job upfront. The SoO pinpoints key systems in the installation, how these systems solve owner needs and which systems will work with each other and in what way. Developing an SoO at the start of a project identifies roles and responsibilities and promotes communication among the key players, especially as installations become ever more complex—and we’ve seen it over and over: lack of understanding among players has served as a barrier to project success.

Recognizing that divergent or unstated expectations often lead to unsatisfactory systems, David Ghatan of CM Kling Lighting Design stated that a Controls Narrative provides an important first step in seeing that all the people involved in a project align their expectations so that subsequent design and implementation decisions advance toward the same goal.

When it comes to installation and setup, things can quickly head south. We need much better education to prepare owners, lighting designers, specifiers, installers and end users what to expect in terms of challenges and outcomes. Manufacturers could provide both a quick guide and detailed installation and configuration instructions, much like you get when setting up your computer, and provide both a print version and an app.

Common terminology across the industry would be extremely helpful to installers—right now. As it is, terminology varies from manufacturer to manufacturer. We must also work toward standardized, common-sense labeling for lighting controls and provide training for facilities personnel who will be responsible for keeping systems up and running for decades to come.

Everyone knows that you can’t solve problems until you acknowledge their existence and appreciate the pain they cause. That’s necessary, but it’s not sufficient. We need to start taking actions that reduce complexity. I encourage manufacturers to adopt open digital protocols for luminaires and controls, such as those referenced in DOE’s L-Prize competition now under way. The design community can simplify approaches to the Sequence of Operations so that its use becomes a matter of routine. And we can surrender some of the needlessly varied vocabulary that makes learning new systems so difficult.

We’re not there yet, and something’s got to give if we in the lighting industry are to make interoperable connected lighting systems a reality.

I welcome your thoughts so please share them with me at ruth.taylor@pnnl.gov.