What is the difference between current LEDs and perovskite LEDs (PeLEDs) in terms of cost to produce (savings), efficiency and effectiveness?

What is the difference between current LEDs and perovskite LEDs (PeLEDs) in terms of cost to produce (savings), efficiency and effectiveness?

Current-generation LEDs are typically made from semiconductors known as III-V (“three-five”) materials (i.e., materials that stem from groups III and V from the periodic table). While these materials are fantastic in an LED configuration, they are also inherently costly to develop. For example, III-V materials are typically grown on expensive surfaces such as sapphire, which can be quite expensive. Alternatively, PeLEDs can be coated from a precursor solution onto glass to create a light-emitting layer that makes them an attractive next-generation technology based on their potential to be inexpensive to manufacture.

In terms of efficiency, III-V LEDs are still more dominant compared to PeLEDs. However, organic LEDs (OLEDs) and PeLEDs have achieved similar efficiencies within recent years. Additionally, since PeLEDs typically have a sharper color purity as compared to OLEDs, they show strong potential for display technologies.

Finally, in terms of effectiveness, PeLEDs still need to be further developed to have the impact that III-V and organic LEDs have had in current lighting technology. By far the largest obstacle preventing PeLED commercialization is its stability. As PeLED stability increases and approaches the lifetime of III-V LED/OLED technologies, it is likely that PeLEDs will be considered for commercial applications in solid-state lighting and displays.

Will PeLEDs face similar challenges to traditional LEDs (e.g., color temperature inconsistency, overheating) or will they address these issues?

As far as solid-state lighting goes, two methods to achieve white light emission involve either designing a blue LED and integrating a downconverting yellow phosphor or building a tandem LED that emits various colors of light that result in broad white light emission. Regarding color temperature inconsistency, both designs will likely face similar challenges as traditional LEDs. This is due to the fact that blue PeLEDs typically employ multiple halides (such as bromide and chloride) within the perovskite layer, which under device-relevant operating conditions may cause the halides to segregate and affect the color of the light emitted. Color stability of perovskite LEDs has improved substantially over the last several years, but investigations on the relevant commercial timescales are still ongoing.

Regarding overheating, given that the materials used in a PeLED typically have poor thermal conductivities, it is likely that overheating will be an issue during PeLED operation, similar to traditional LEDs; however, recent techniques have been identified that may be able to help with this issue.

What is the biggest challenge to the development and adoption of PeLEDs?

Hands down, the biggest challenge in the overall adoption of PeLEDs is their stability. For an LED technology to be commercially viable, it needs to reliably emit light for at least 10,000 hours, which is still a significant challenge for PeLEDs.

How has your research specifically addressed this challenge?

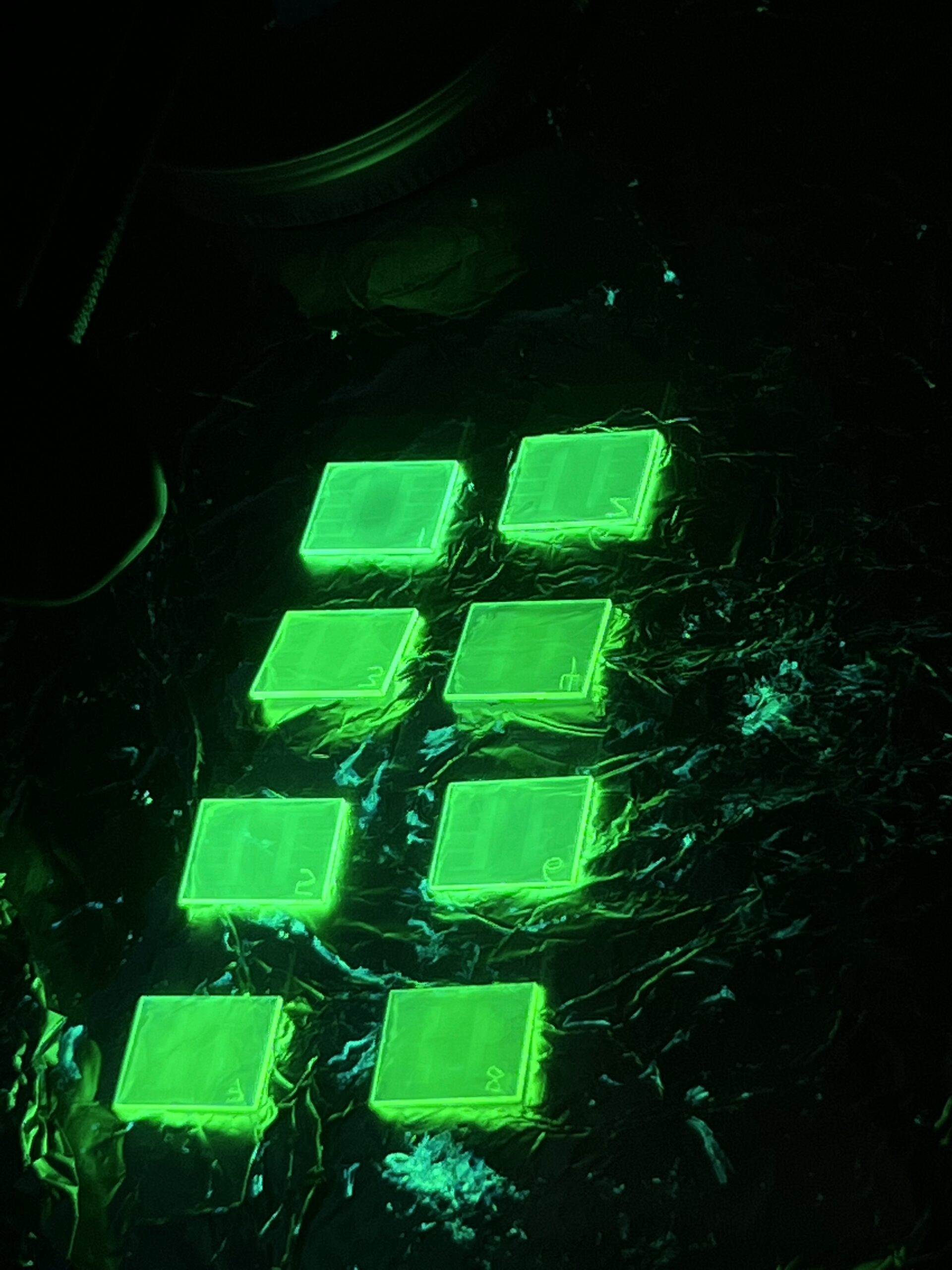

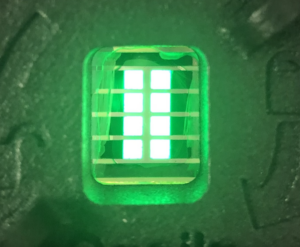

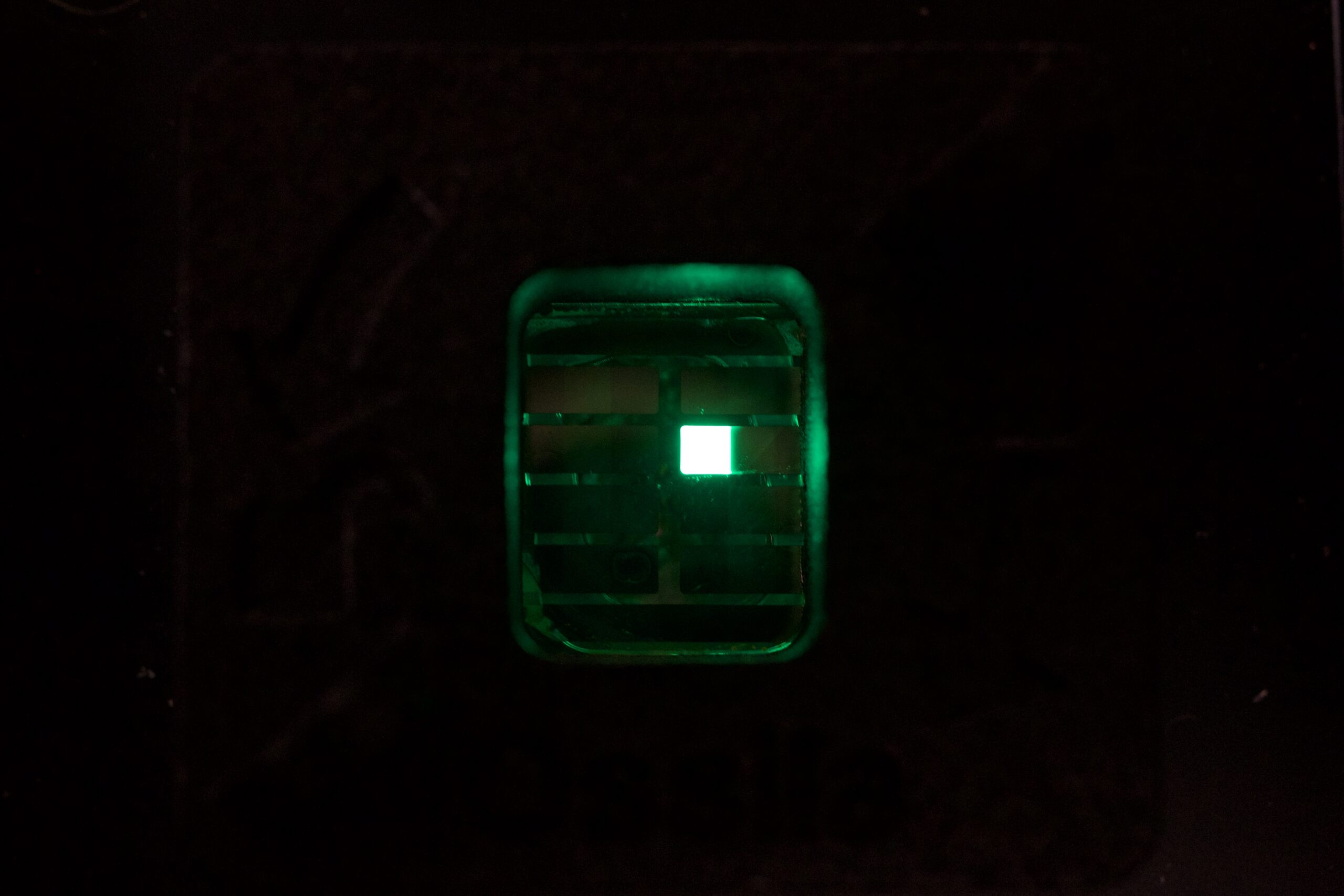

At the heart of our paper [“Trade-off Between Efficiency and Stability in Mn2+ Doped Perovskite Light-Emitting Diodes”], we analyzed both the efficiency and stability of manganese-doped PeLEDs with respect to the concentration of a molecular additive known as tris (4-fluorophenyl) phosphine oxide (TFPPO). While the efficiency of our PeLEDs improved by nearly five-fold, their stability was also impaired by nearly 15-fold with increasing TFPPO concentration. While phosphine oxide additives show strong potential to enhance PeLED performance, one must carefully consider both the efficiency and stability of PeLEDs on the road to commercialization.

Some highlights from our research include achieving a maximum luminance of 128,000 cd/m2, which is among the brightest reported PeLEDs, and a 14.0% external quantum efficiency, which is among the most efficient reported B-site doped PeLEDs.

As stated, stability is still the largest issue remaining. In our study, we achieved stability lifetimes ranging between 2 and 37 minutes, which is not sufficient for commercial applications. However, we note that the understanding between this trade-off between efficiency and stability will help us understand the effects of phosphine oxide additives on PeLED performance in general.

Where are you with current PeLED research? Is there an estimated timeline for adoption?

Our group, as well as others, have been working toward enhancing PeLED performance in terms of brightness, stability, efficiency and integration with other technologies. Considering that the PeLED community is approximately 10 years old (one of the first PeLEDs was demonstrated in 2014), and that a majority of the work thus far has been geared toward enhancing the efficiency across various colors (such as red, green and blue), PeLEDs will be adopted when stability issues are mitigated further, which likely involves at least another 5 to 10 years of research. Similar to OLEDs, red and green efficiency and stability has increased more rapidly than blue.

Are there specific commercial applications where PeLEDs would be more effective than traditional LEDs? Do you foresee it replacing current LED technology entirely?

PeLEDs tend to emit with sharper color purity as compared to OLEDs. In other words, a blue is more blue and a red is more red. This means that next-generation displays could be dominated by PeLEDs as opposed to OLEDs due to the potential for sharper color resolution, inexpensive materials and simple fabrication.

Can you put the potential success of PeLEDs in perspective in terms of how it will affect the lighting industry as a whole? Is it more of an incremental step in the evolution of LEDs or a giant leap?

Regarding solid-state lighting, according to a U.S. DOE solid-state lighting report, if the DOE targets for efficiency are met, approximately 78 quads of energy will be saved through 2035, which is equivalent to around $890 billion saved in energy costs. Thus, given PeLEDs’ inexpensive processing costs, they could play a role in meeting these DOE targets.

In terms of next-generation displays, the sharp color emission from PeLEDs coupled with their inexpensive processing costs has the potential to enable both better and cheaper screens for our phones, computers, TVs and watch screens. Considering our increasing reliance on our screens for work and entertainment, making an impact in this sector also has profound consequences.

Additionally, PeLEDs are not limited to the visible spectrum. Our group is working toward developing perovskites that can emit ultraviolet (UV) light, which have promising applications in human health, 3-D printing and nanofabrication. Carefully engineering these UV PeLEDs will increase their commercial viability for these additional applications.

Thus, the commercialization of PeLEDs would be a game-changer for the lighting industry as a whole.