An update on the Yuma pilot project findings

By Andrea Wilkerson

From the cold tundra of Alaska to the hot deserts of the Southwest, high-flux lighting applications are ubiquitous in the U.S., encompassing street and area lighting in addition to more-specialized uses at correctional facilities, military bases and other such places. But combining high-flux lighting applications with high-temperature environments poses a challenge for LED luminaires, because the higher the luminous flux, the harder it can be to dissipate heat to prevent damage to luminaire components. To learn more, the U.S. Department of Energy’s (DOE) Gateway program evaluated LED luminaire performance in the Yuma (Arizona) Sector Border Patrol Area along the U.S.-Mexico border, where temperatures reached as high as 120 deg F during the nearly four years of performance evaluation.

TRIAL INSTALLATION

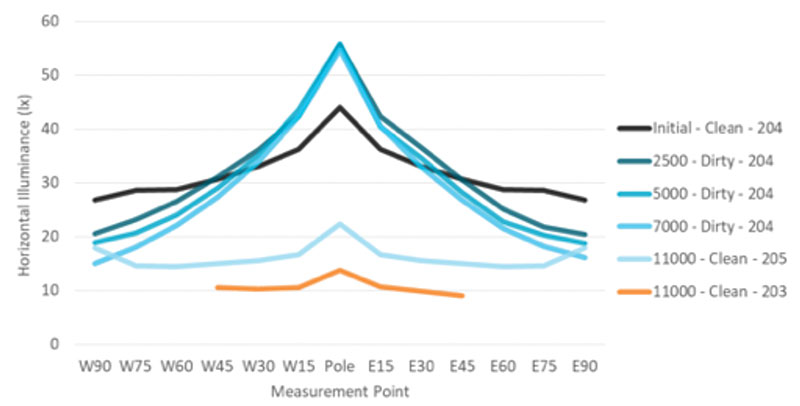

In February 2014, two LED luminaires were installed on each of three sequential poles as part of a trial installation for a DOE Federal Energy Management Program Energy Savings Performance Contract ENABLE project. After installation, illuminance was measured at points in a rectangular 15-ft grid covering a 180-ft by 125-ft area surrounding one of the poles. Illuminance measurements at the same grid points occurred again in September 2014 at 2,500 hours of operation, in March 2015 at 5,000 hours of operation, and in September 2015 at 7,000 hours of operation.

The distribution of light from the LED luminaires changed in the first 2,500 hours of operation, with illuminance values measured nearest to the pole increasing, while the greatest decreases were at the points farthest from the pole. This distribution trend persisted after 5,000 and 7,000 hours of operation, along with an overall decline in measured illuminance. While the cause of these changes is unknown, it was expected that dirt depreciation was the main culprit. After the 7,000-hour measurements, the two luminaires on the measured pole were removed and tested at a nearby photometric laboratory and then shipped to the luminaire manufacturer’s photometric laboratory for additional photometric testing. The testing confirmed the considerable effect of dirt not only on lumen output, but also on the distribution of light exiting the luminaire.

The first-generation LED system was measured a final time in September 2016 at 11,000 hours of operation after the luminaires had been cleaned; however, this time the illuminance measurements were recorded in the areas surrounding the other two poles, since the first-generation luminaires had been removed from the pole that had originally been measured. The measured illuminance at 11,000 hours had decreased by more than 50 percent compared to the initial illuminance measurements in February 2014. The cause of this unexpected result is still being investigated.

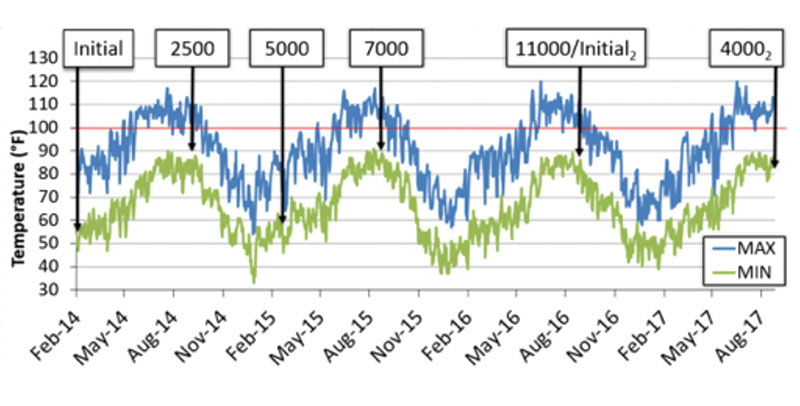

The two first-generation luminaires removed for testing in September 2015 were replaced with two second-generation luminaires, each outfitted with nine thermocouples that collected thermal data every minute over the course of a year. Each luminaire had six thermocouples placed at the temperature measurement point (TMPLED) of select LED packages, one attached to the interior top surface of the luminaire housing, and one attached to the temperature measurement point (TMPPS) of one of the LED drivers. An additional thermocouple measured the ambient air temperature outside each luminaire. The LED packages always experienced the greatest range in temperatures throughout a given day, no matter the ambient temperature. On the hottest ambient-temperature day, the LED package temperatures were warmer during the day when not operating than on the coldest ambient-temperature night when they were operating.

FULL INSTALLATION

A second-generation LED system was installed in the fall of 2016 on more than 200 poles along the U.S.-Mexico border in the Yuma Sector. Illuminance and spectral power distribution (SPD) measurements of this second-generation system were recorded in September 2016 and again in August 2017 at 4,000 hours of operation. The second-generation LED system at 4,000 hours of operation was found to be performing similarly to the first-generation system at 5,000 hours of operation.

One difference was that the second-generation luminaires exhibited colorover-angle variability that produced noticeable color differences on the illuminated sand beneath the system. Higher CCT values were recorded closest to the pole, and lower CCT values were recorded farther away from the pole. These color variations were documented during the initial measurements taken shortly after the luminaires were installed, and remained at the time of the 4,000-hour measurements. Additionally, the measured SPDs and related color characteristics for the second-generation luminaires changed to a greater extent than expected over 4,000 hours. The high-temperature environment in Yuma may have caused or at least contributed to these effects, although luminaire design characteristics can also contribute to accelerated shifts in SPD.

KEY TAKEAWAYS

The LED lighting systems installed in the Yuma Sector provided considerable benefits in energy reduction, approximately 69 percent per pole for the second-generation system, along with improvements in uniformity and considerable maintenance savings. However, lumen and color maintenance, luminaire efficacy and luminaire component lifetimes remain considerable concerns when LED luminaires are exposed to high ambient temperatures. The evaluation in Yuma also raises several considerations as the solid-state lighting industry advances.

Dirt depreciation factors. Careful optical design may lead to superior illuminance uniformity during pre-installation photometric analyses; however, the Yuma investigation shows that the uniformity can change considerably as the luminaires accumulate dirt. In outdoor settings, dirt depreciation factors and the effect of dirt on distribution are still necessary considerations with solid-state lighting because of its long lifetimes.

Color-over-angle testing. The color variability documented in Yuma may not be as noticeable in other applications, since it is a visual evaluation that is not commonly found in most exterior applications. Still, the evolution of solid-state lighting technology is changing the data needed to evaluate the performance of products and systems. Determination of SPD and related color metrics at different angles is not currently included as part of standardized outdoor luminaire photometric testing, but may be necessary for certain outdoor applications.

Laboratory-derived performance data. Relevant LM-80 data reviewed by DOE for this project indicated no depreciation in light output over 10,000 operating hours, even at a case temperature of 105 deg C (221 deg F). The development of relevant testing and reporting procedures and metrics of acceptability necessarily lags behind the identification of the need for certain types of data. Continued improvement of test methods and standards for LED luminaires, as well as new approaches to product and system development, are needed to better characterize performance of LED lighting systems. Additional testing considerations include on/off switching and depreciation caused by solar thermal loading.

With more than 40 reports over the last 10 years, the DOE Gateway program has documented both the advantages and the challenges of many different SSL applications. The multiyear evaluation of the LED installation in Yuma also serves this purpose; while the initial energy, lighting quality, and maintenance benefits relative to the incumbent system were well documented and produced satisfactory results, the evaluation raises questions regarding the long-term performance of LED systems in high-temperature environments. Ongoing improvement of current test uation raises questions regarding the long-term performance of LED systems in high-temperature environments. Ongoing improvement of current test LED lighting systems.

To learn more about the background and details of this multiyear evaluation, visit the DOE SSL Gateway Outdoor Projects web page (https://energy.gov/eere/ssl/gateway-outdoor-projects).