In 2021, when the U.S. Department of Energy (DOE) designed a new $12 million lighting competition, or “L-Prize,” targeting commercial sector lighting, we set the bar for entrants high, with ambitious innovation goals across the board. We intentionally structured the competition to offer a variety of innovation opportunities and multiple pathways to win.

We also wanted to focus specifically on the environmental aspects of new lighting ideas. To us, the new competition provided a golden opportunity to promote the integration of environmental sustainability into an entrant’s design approach.

The lighting industry has traditionally approached sustainability through energy conservation, which occurred organically through the transition to LEDs. LEDs achieved a major reduction in energy use, as well as in associated carbon emissions. But the lighting industry has been slow to adopt other sustainability approaches, such as materiality, circularity principles or embodied carbon reporting.

With the L-Prize, the DOE expanded the meaning of exceptional lighting performance to include material sustainability, transparency reporting, equity and product design principles for a circular economy. We asked for a lot, and the Prototype Phase winners announced in October 2023 delivered.

The L-Prize Product Life Cycle requirements sought new ideas for a luminaire to maintain or reduce energy use over its lifetime. We wanted to see extended useful lifetime, reduced use and extraction of harmful materials and decreased operational and embodied carbon impacts by using approaches like modular design or use of innovative or biodegradable materials.

The Product Life Cycle section included minimum driver lifetime, chromaticity and lumen maintenance requirements. When we keep products and components in use longer, there is less early-stage environmental impact because we are reducing the need for more material extraction as well as decreasing manufacturing and production costs.

We required circular design in the entered luminaires, which were defined as minimizing raw resource inputs as well as minimizing waste, pollution and carbon emissions by keeping everything in use for as long as possible. Shifting from a linear pathway to a circular one in the lighting industry involves changing structures, economies and practices. Points could be earned using the Chartered Institution of Building Services Engineers (CIBSE) TM66, which is both a technical memorandum and a design tool that was developed to specifically address circular design in the lighting industry. It is a great tool to use in early design phases for holistic integration of circular principles. Competitors entered information about the products and design choices they had made, and the tool provided a circularity score from 0 to 4 that the L-Prize Expert Reviewer Panel then compared against the physical prototypes. This change needs to start somewhere, so why not build it into the earliest design stages—like the Prototype Phase of the L-Prize?

Finally, we looked at Materials and Sustainability Innovation and awarded bonus points for new ideas that support improved material transparency or material health. Material transparency refers to the disclosure of the ingredients used to create materials or products, and their potential human health effects, environmental impacts or social equity in manufacturing, recycling and disposal. Material health describes the sustainability quality or “health” of the materials and how these materials may affect humans and ecosystems. Material health also includes knowledge about the chemicals used in products across their supply chains and information about any chemicals of concern.

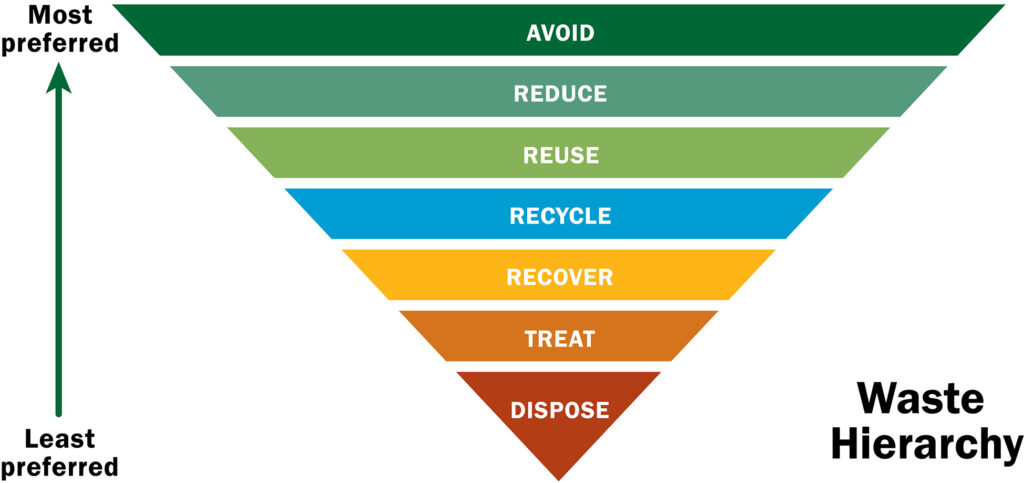

We encouraged end-of-life opportunities for the luminaires other than final disposal: reuse/ remanufacture, recycling or energy recovery. Of course, reuse/remanufacturing is the best-case scenario, when products are uninstalled and put right back into use again either directly as a whole luminaire or through the remanufacturing of components into new luminaires. With recycling, a luminaire is taken apart and the components are melted or broken down for use as raw materials, which involves more energy and embodied carbon to return the material to a place where it can be used again as a raw material. Recovery occurs when a product can’t be taken apart for a variety of reasons—it was glued together or has a coating that was sealed onto it. In such cases, the product must be shredded or burned.

Given our expansive sustainability wish list, what Product Life Cycle innovations did the Prototype Phase winners present? I’m excited to say that the three luminaire track winners delivered. Their winning prototypes represent ground-breaking innovation in environmental sustainability. Here are the innovators that are leading the way in sustainability in lighting:

- Lightly developed a low-carbon, architectural-grade linear luminaire, utilizing locally sourced materials grown in the U.S. The high-efficacy luminaire is made of locally harvested tulip poplar and wool felt instead of aluminum, steel, plastic and PET felt, significantly reducing the luminaire’s embodied carbon. It also included a Declare label, providing material transparency, and stated that the luminaire is 95% biodegradable and 3% recyclable, with only 2% heading for a landfill.

- GiEBA (Grid interactive Efficient Building Alliance) developed an architectural-grade 2-ft by 4-ft troffer that continuously reads and reports critical performance and operational data, allowing predictive maintenance software to spot problems in advance to potentially extend product lifetime. The luminaire is designed for disassembly with modular components and easy-to-follow end-of-life diagrams for disassembly and recycling.

- Signify developed a luminaire with a highly modular design and lightweight form factor using additive manufacturing via printed electronics, 50% reduction in number of luminaires used, 50% reduction in embodied carbon, and reversible, click-and-stamp assembly to honor the circular economy philosophy. In terms of the overall technical requirements, all the winners in the Prototype Phase demonstrated extraordinary performance and capabilities. Winning luminaires overcame historical tradeoffs between efficacy and quality of light to achieve over 160 lumens per watt with exceptional quality of light performance. All winning luminaires are digitally interoperable with other luminaires and connected systems using the D4i protocol, moving beyond the shortcomings of analog 0-10-V and proprietary interfaces.

The bold innovations presented by our entrants have me excited for the third and final phase of the L-Prize— Manufacturing and Installation— and its fresh opportunities for awards and recognition. As with the first two phases, past participation is not required; all eligible entrants are welcome to join the competition. The final phase will reward U.S. manufacturing and installation of lighting systems that meet our rigorous L-Prize technical requirements.

Kate Hickcox is a lighting research scientist at Pacific Northwest National Laboratory. She is a creative thinker in the field of lighting, focusing on sustainability as well as equitable lighting solutions for communities and the environment.