Introduction

IES LM-85, Approved Method: Optical and Electrical Measurements of LED Sources, as shown in Figure 1, is the IES standard that applies to LED component measurements. 1 LM-85-23 covers the same topics as its predecessor, LM-85-14, but it is a substantial rewrite that improves the methods in LM-85-14 and adds several new testing methods, including two that are based upon a novel technique, previously considered a proprietary trade secret, that increases measurement accuracy by roughly 100X.

LM-85 also now truly ties optical measurements to junction temperature, TJ, eliminating a significant error source present in many LED measurements. Using the updated and new LM-85 methods, LED measurements will now be more consistent when performed at different laboratories.

Temperature-referenced measurements will also give product designers something they haven’t had before: accurate LED-output-vs-temperature data. Using this data, designers can create LED products with improved thermal optimization. These products promise to be more efficient, less costly, and more reliable.

LM-85-23 came about because of a unique collaboration that occurred during the COVID pandemic. With most of the world locked down, the scientists and engineers (from Australia, Germany, Japan, and USA) in charge of LM-85 worked overtime to refine the standard; the resulting document will likely be considered a breakthrough in the field. This article provides an overview of LM-85’s innovative methods and details the history of the document’s development.

LM-85 Overview

LM-85 presents a palette of measurement methods that suit different purposes:

- The DC method, for accurate measurement of calibration standards

- Single-Pulse methods, for rapid measurements and production binning

- Continuous-Pulse methods, for accurate characterization and production testing unaffected by junction heating

LM-85 also includes a helpful annex with a procedure for determining the junction-temperature rise resulting from a pulsed waveform, and one method for identifying a phenomenon called the transient-voltage anomaly.

The new LM-85-23 standard is 46 pages; LM-85-14 was 12. The increase is more than a few new methods: LM-85 now has much more in-depth information about the science behind the measurements and more detailed procedures with diagrams and flowcharts, such as the Single Pulse procedure flowcharted in Figure 2. LM-85 also provides the rationale behind measurement steps and instrumentation choices, along with an estimate of the likely measurement uncertainty associated with any given method. This information allows scientists and engineers to pick the best-suited method for a particular situation – maximizing measurement accuracy, while enhancing measurement throughput.

LM-85-23’s Development Story – COVID Creates an Opportunity

LM-85-23’s development began as a scheduled minor update of LM-85-14, but then morphed into a substantial rewrite that includes several new methods that offer greatly improved accuracy. These methods use new techniques to eliminate error sources that have degraded measurements since high-power LEDs were invented. One of these, LM-85’s Mean Differential Continuous Pulse (M-DCP) method, was considered novel enough to be published in NIST’s Journal of Research2.

LM-85’s story involves people: key experts scattered around the world, working during a difficult time – the COVID pandemic. LM-85’s revision was just underway when COVID began, and in keeping with government guidelines, IES face-to-face meetings were halted. Within the LM-85 working group, at first it wasn’t clear that any progress could be made. Traditionally, most standards development occurred at face-to-face meetings, which happened a few times per year. Between those meetings, occasional conference calls allowed discussion of specific details.

Without the in-person meetings, it seemed that the updating of LM-85 might have to be tabled until after the pandemic. But something unusual happened during the first conference call after shutdown – the scientists and engineers were keenly and intensely engaged in the technical discussion. It was apparent that these busy experts now had available something that previously had been in short supply – time.

Yuqin Zong, the working group leader, recognized this unique situation and immediately took advantage of the idled talent. He set up 1.5-hour weekly group calls. That pace was unprecedented: due to meetings and other commitments, nobody ever had that much time in their schedule. Furthermore, the laboratory research or writing homework assigned during a call also took significant time. But that barrier was gone. Throughout the COVID lockdown, the working group met weekly for about eighteen months. In between meetings, there was time to write and to experiment. An experimental measurement laboratory was set up in San Diego at the unoccupied facility of Vektrex, a test-equipment maker. That lab, which had high-performance current sources that could produce accurate short drive pulses, was used to prototype new measurement methods. Scientists from major LED manufacturers, including Osram, Lumileds, and Cree, sent test devices to Vektrex to be used in the research: high-power devices to test methods for junction temperature assessment, amber devices to test temperature sensitivity, and phosphor-converted devices to test phosphor-related measurement errors. At each call, experimental results were presented and evaluated, and often new areas of research were suggested. The experts in the group collaborated to perfect and document the emerging test methods.

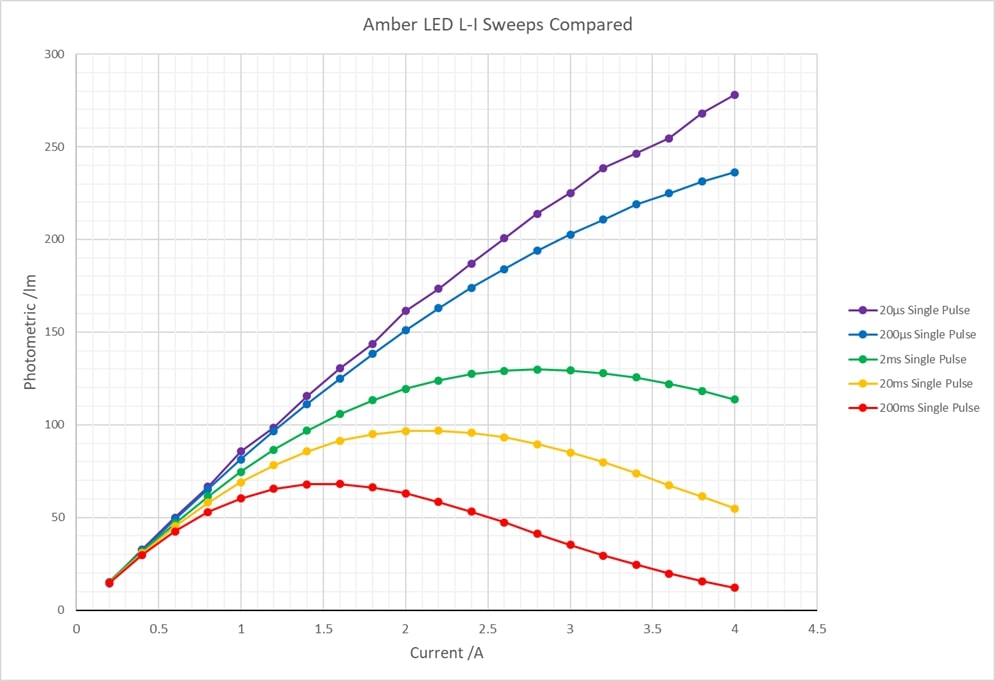

For those accustomed to the usual glacial pace of standards development, the rate of progress was astonishing. Once it became clear that the working group was substantially rewriting the standard and that time was nearly unlimited, the experts freely contributed their best ideas and experience. Lumileds’ Seng Hup Teoh shared the idea of using amber LEDs (which are the most temperature-sensitive) to validate methods. The group’s experiments with the amber LEDs quickly showed that using shorter current pulses when driving was beneficial, otherwise junction heating reduced the LED’s output. But short current pulses were difficult to produce, and the shortest pulses actually increased measurement uncertainty, due to pulse shape distortions and other factors. This effect can be seen in the variations in the 20-µs plot line in Figure 3.

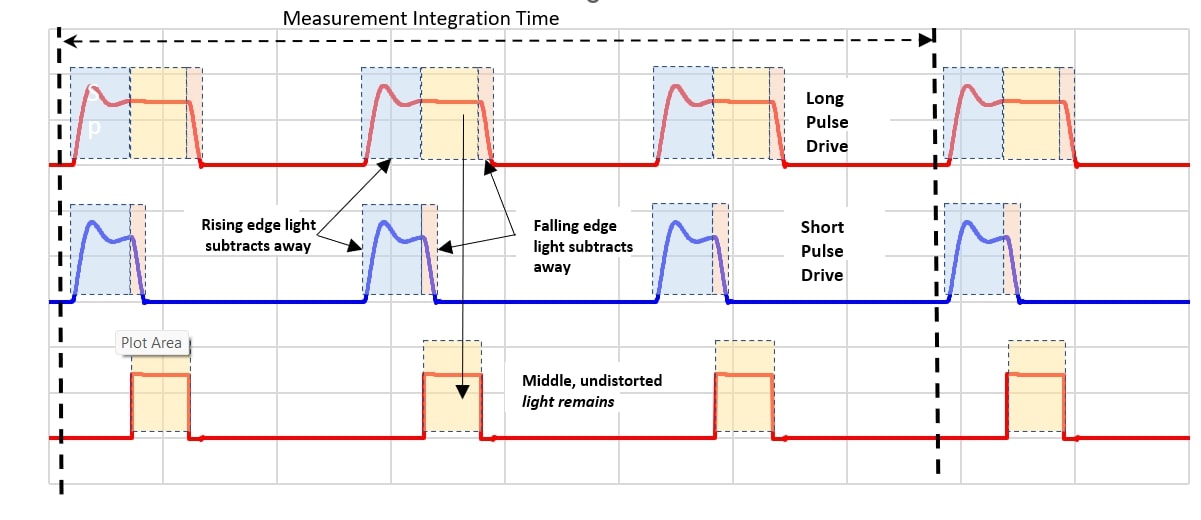

Osram was the first to contribute a method for short pulse uncertainty reduction. Dr. Markus Schneider presented Osram’s “flash pulse” method, a technique that used roughly 1 ms pulses, along with a correction factor obtained with a photodiode and oscilloscope. Flash pulse was a step forward, but it required additional equipment, it still suffered from some heating error, and it was unable to correct spectral measurements. During the September 3, 2020, call, Nichia’s representative Yoshiki Yamaji then presented a far-superior method that Nichia itself had been using for years – the Differential Continuous Pulse (DCP) method, shown in Figure 4.

Yamaji had recently introduced the DCP method at the International Commission on Illumination’s TC2-91s working group. TC2-91, headed by Dr. Schneider. According to Saori Mitsuhashi, Nichia’s Global Standardization Project Coordinator, DCP was invented by Nichia engineer Shinya Yamaoka in 2015. Yamaoka was working in the optical measurement department on the development of super high VF products, and he noticed a measurement error. As Mitsuhashi explained in an understated email, “while gradually increasing the pulse width and searching for rise errors while minimizing the effects of heat, he had the inspiration to use subtraction.”

Coincidentally, DCP had also been independently developed by Fahong Jin at Lumileds. Both Lumileds and Nichia had considered the method to be a proprietary trade secret until 2020, when Nichia decided, for the good of the LED industry, to make it publicly available in the standard.

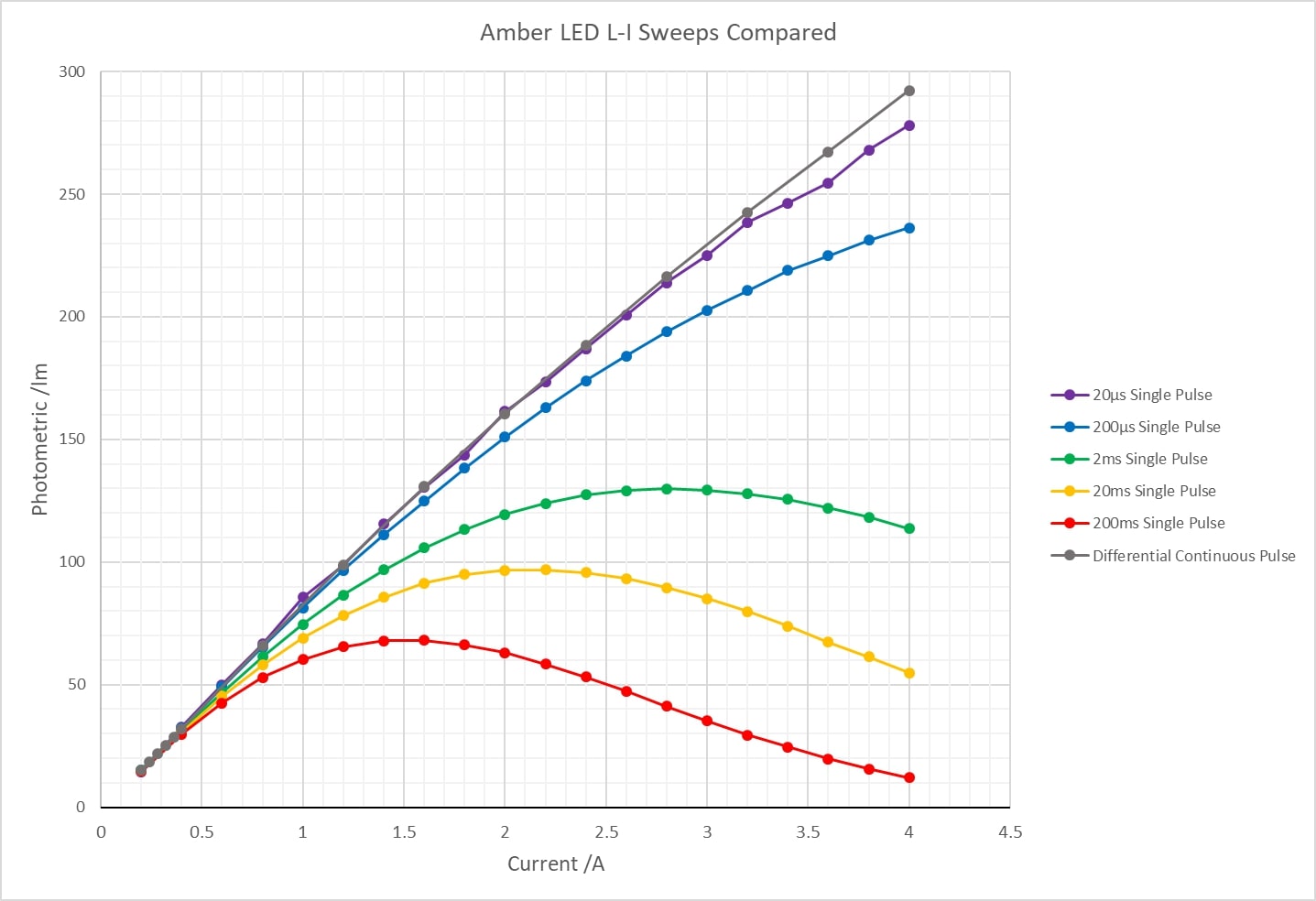

The DCP method’s short pulses reduced junction heating, eliminating the output decline observed in Figure 3. More importantly, DCP eliminated the measurement errors caused by distorted drive pulses. The resulting DCP L-I plot, shown in Figure 5, was nearly linear, aligning closely with the LED’s expected performance.

While DCP’s incorporation into LM-85 might seem to be a fortuitous coincidence, it is a great example of the IES standards process. The scientists in the LM-85 working group had a common goal: to overcome the short-pulse measurement errors. As discussions occurred and problems were identified, knowledge that was once proprietary was shared. That led to additional discussion and disclosure and eventually to an elegant solution that achieved the goal. That solution was then incorporated into the standard, to be made available to all who work with LEDs.

LM-85’s Payoff – Better Measurements and Improved Products

The physicist Lord Kelvin, inventor of the Kelvin temperature scale, is quoted as saying, “If you cannot measure it, you cannot improve it.” This insight is certainly applicable to LED lighting products. Light is difficult to measure, and when that light is generated by a temperature-sensitive device like an LED, it compounds the problem.

To date, most published LED device data has included hidden uncertainty resulting from temperature shifts during measurements. To address this uncertainty, product designers often add safety margins by enlarging heatsinks or adding more LEDs. When the uncertainty is extreme, they may be forced to adjust or degrade product lifetime or performance specifications.

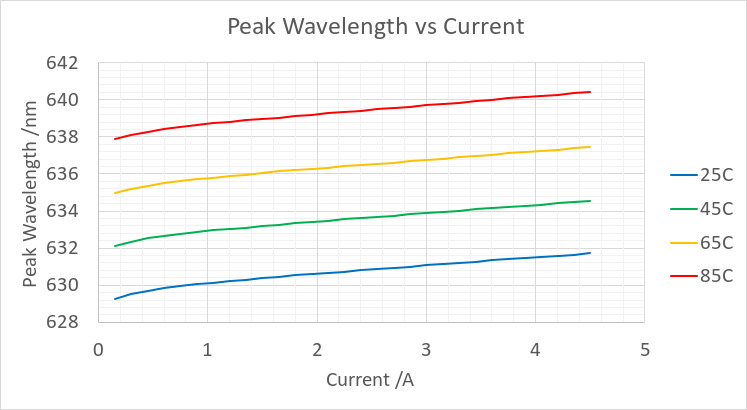

LM-85’s improved methods give LED manufacturers another, better choice: design with accurate data and create efficient, thermally-optimized products. For example, the German photonics company Jenoptik utilized LM-85’s methods to characterize an LED used in a light-source redesign.3 The previous version of the light source (a pulsed red-light illuminator) suffered from poor wavelength stability, leading to customer complaints. Using LM-85’s DCP method, Jenoptik analyzed the wavelength vs current and temperature characteristic of a replacement LED that had better stability. The resulting data, shown in Figure 6, was used to confirm that stability, and then to tune the light-source’s drive electronics to match that LED’s characteristic. After the redesign, the optimized source no longer exhibited wavelength instability; all customer specifications were met.

The Post-LM-85 World

Although LM-85 was released just recently, its impact has already been substantial. A sister standard, LM-92, Approved Method: Optical and Electrical Measurement of Ultraviolet LEDs—also developed during the COVID pandemic—has incorporated the DCP and M-DCP methods. NIST scientist Dr. Cameron Miller now uses DCP for optical calibrations, and DCP measurements are under consideration for inclusion in an IEEE standard for UV-LED datasheets. Many LM-85 authors, now back to their busy post-lockdown schedules, are applying the method within their organizations.

A 100-fold improvement in optical measurement accuracy has not gone unnoticed in the wider optoelectronics industry. Although LM-85 was originally designed for LEDs, its methods have also been embraced by laser companies seeking more precise power-vs-current curves. These companies produce critical components for cell phones, communication systems, and displays – products integral to our daily lives.

While COVID was a challenging time for the world, we can now, thanks to the contributions of the IES LM-85 working group, look forward to improved light-enabled products, made possible by LM-85’s measurements.

1 Illuminating Engineering Society LM-85-23, Approved Method: Optical and Electrical Measurements of LED Sources, available at https://store.ies.org/product/approved-method-photometric-testing-of-indoor-luminaires-using-high-intensity-discharge-or-incandescent-filament-lamps-lm-85-23/?v=0b3b97fa6688.

2 Zong Y, Hulett J, Koide N, Yamajii Y, Miller C. Mean Differential Continuous Pulse Method for Accurate Optical Measurements of Light-Emitting Diodes and Laser Diodes. J Res NIST. 23 Nov. 2021. Online: https://www.nist.gov/publications/mean-differential-continuous-pulse-method-accurate-optical-measurements-light-emitting.

3 Housand, B Compact, High Output, Pulsed LED Light Engine Design by DCP, Council for Optical Radiation Measurement Conference, 14 Nov. 2022, available at https://cormusa.org/wp-content/uploads/2024/01/3-CORM2022-Metrology-Houssand.pdf.

4 The DCP method is further improved by determining the mean values of the short and long pulse trains using a digital multimeter with high accuracy. This improved method is called the M-DCP method2 M-DCP significantly reduces the measurement uncertainty resulting from the pulse amplitude, pulse width, and pulse jitter of the current source.